Fall Arrest Harness Inspection System

Falls from height remain the biggest cause of death in the workplace with an average of 45 fatalities and 3,750 major injuries every year in the UK.

The Work at Height Regulations 2005 (WAHR) places duties on employers and duty holders concerned with managing or carrying out work at height. In addition to the legal requirements for inspections in WAHR, BS EN 365:2004 and BS 8437 also contain information on periodic inspection of fall protection equipment.

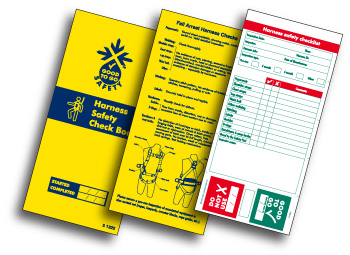

Good to Go Safety™ system for fall arrest harnesses allows the quick and easy inspection and tagging of harness. Use a harness checklist to ensure equipment safety during work at height.

The need for inspection:

There is a wide range of potentially harmful/damaging effects on a harness - ranging from general wear and tear (abrasion, dirt etc) to abuse and impact force from falls. A harness can be life-saving during a fall so the need to carry out regular equipment checks is critical. Most devices will carry a lifespan or obsolesce date, as determined by the harness manufacturer and should be adhered to at all times.

A competent person should establish a regime for the inspection of equipment to include frequency, actions, recording, monitoring and training. There are varying levels of inspection:

- Pre-use checks; to be carried out every time before the harness is used - it should be a visual and tactile examination of the harness, carried out in good light. The entire harness should be checked and should normally take a few minutes to complete.

- Detailed inspections; formal and comprehensive inspection before first use and at least every 6 months thereafter. If the harness is in frequent use this time span should be reduced accordingly.

- Interim inspections; are similar to detailed inspections but may be required more frequently in cases with a high risk of equipment deterioration (eg. working with chemicals, paint, grit blasting etc).

If there is no evidence that an inspection has been carried out - in line with the regime - it should be withdrawn and passed to a competent person for a detailed inspection. It is also important for a procedure to be in place to quarantine defective harnesses and to ensure they can not go back into circulation.

Keeping suitable records:

Apart from your legal standpoint, good record keeping can help establish the age and conditions of use for your harnesses. WAHR stipulates the need for records to be kept of all completed inspections, a copy of which should be kept on site until work is completed and thereafter at an office for a further 3 months.

Good to Go Safety™ delivers on a number of levels. Each check book provides 25 individual pre-use inspection checklists, automatically producing a carbon copy which is retained in the book as part of the audit trail. Once satisfied the harness is safe for use, a "Good to Go" tag is clearly visible for all to see. Likewise if a fault is found a "Do Not Use" tag indicates the harness is in quarantine. A tamper evident seal ensures that these displays are accurate and up-to-date at all times.